Startups can’t do things the same way big companies do. And that’s a good thing; here’s why.

Startups and big companies differ in a lot of ways. When it comes to hardware, the gulf between the two is massive. Early-stage startups are painfully under-financed. This lack of capital makes manufacturing one of the most critically dangerous periods in a young company’s life. One tiny mistake in a design, tool, or QC process and BAM, you’re out of business.

There are no second chances in hardware.

At least once a week, I have a conversation with a founder that wants to design something that mimics an Apple product. Maybe it’s a surface with no ejector pin marks, or some complex texturing, or laser drilled holes, it doesn’t really matter: it’s impossible for a startup to do certain things. “But no,” they say, “Apple does it. Why can’t I?”

Apple is an exception to nearly every rule.

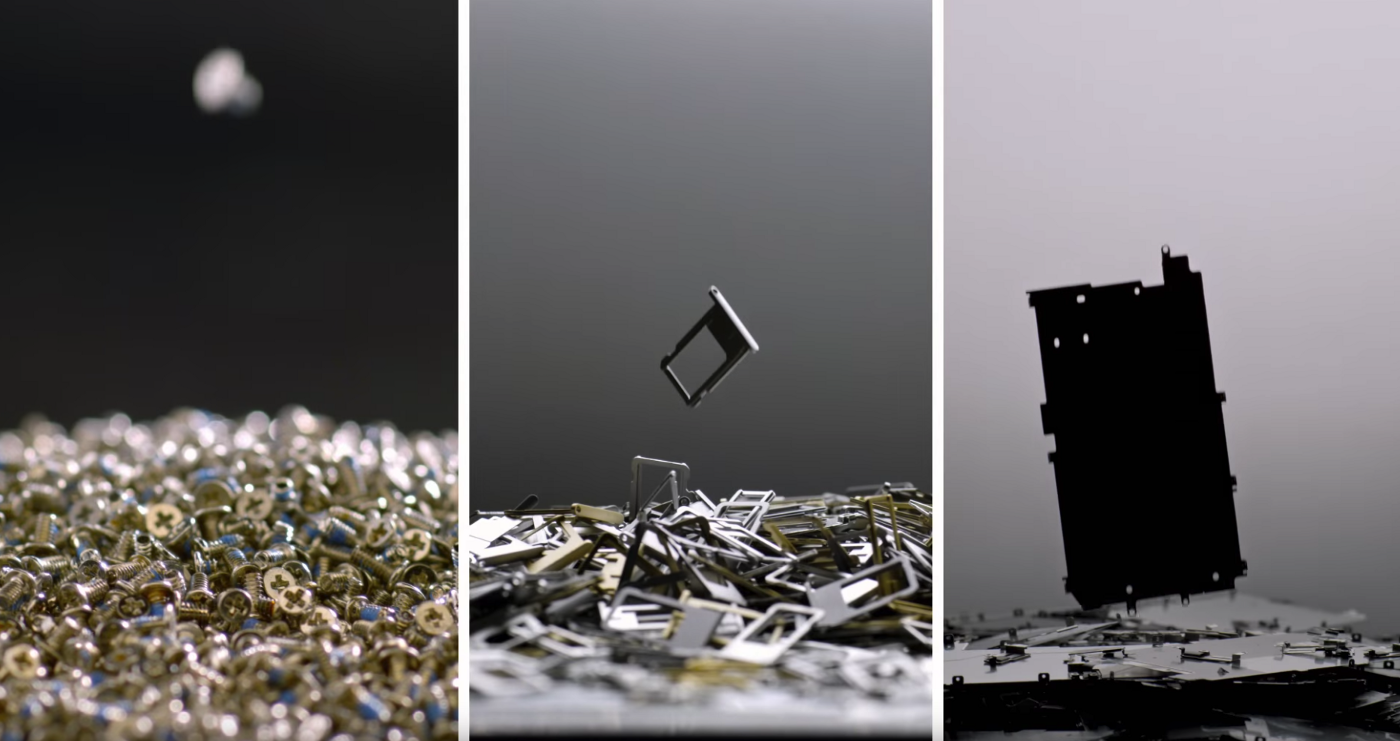

What happened when Apple wanted to CNC machine a million MacBook bodies a year? They bought 10k CNC machines to do it. How about when they wanted to laser drill holes in MacBook Pros for the sleep light but only one company made a machine that could drill those 20 µm holes in aluminum? It bought the company that made the machines and took all the inventory. And that time when they needed batteries to fit into a tiny machined housing but no manufacturer was willing to make batteries so thin? Apple made their own battery cells. From scratch.

Pretty much no company, big or small, can afford to do these things. Yes, Apple has done a great job building many of these products and yes, consumers have come to love many of these difficult-to-manufacture features. But you are not Apple. So long as you’re providing value to your customers, taking the fit and finish of your product down a notch is okay. Especially for your first few production runs.

So what should you avoid? Here’s a few things that Apple often does that can cause problems for a startup:

- White plastic

White is of course the most difficult color to mold. If you NEED to use white, never have two separately molded white-on-white parts. They will never be perfectly color matched. - CNC machining at scale

CNC machining is fantastic for prototypes and pretty awesome for high margin parts like hip implants and turbine blades. It is not for consumer devices. Figure out a way to cast your metal parts. - Laser drilled holes

Invisible laser drilled holes are far more difficult to make than it may seem. You can usually accomplish a similar look and feel without the complex secondary operation if you’re willing to sacrifice a bit. - Molded plastic packaging

Many small Apple products come in polycarbonate + ABS/PC mix molded packaging. This is both harder and more expensive than you might think. Recycled cardboard is your friend - No ejector pin marks

Unless you’re a billionaire genius, your product will have noticeable ejector pin marks. A good CM knows how to hide these well. Nearly zero CMs hide them as well as Apple does. Embrace it. Most consumers don’t know what the hell an ejector pin mark is anyways. - 4-color, double-walled, matte boxes + HD foam inserts

I know you’re going to do this anyways, but be aware that these kind of boxes will literally be the most expensive line item on your BOM. It’s not unusual for them to cost upwards of $12/unit at scale. And then they get thrown away.

There are many more. If you see a feature on an Apple device you want to copy, try to find it on another company’s product. If you do, it’s probably okay to design into your product. Otherwise, lower your expectations. I assure you it’ll be better for your startup.

Ben Einstein was one of the founders of Bolt. You can find him on LinkedIn.

Bolt invests at the intersection of the digital and physical world.