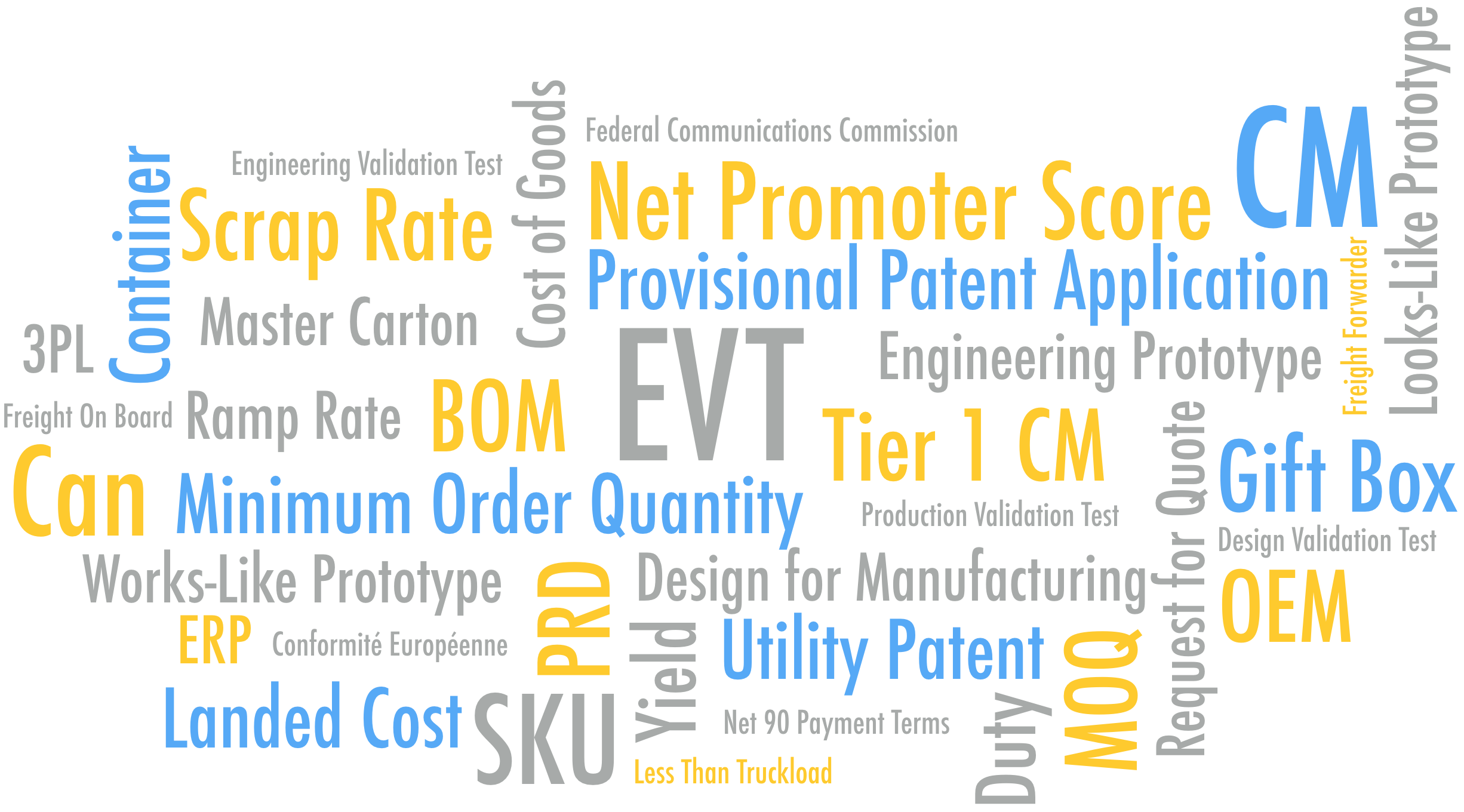

One of the most frustrating elements of any specialized field is the endless list of acronyms and jargon. Acronyms can be tough to avoid, but jargon has the painful side effect of making people feel inferior and unwelcome when trying to learn about a new field.

Hardware startup founders, employees, investors, and distributors are plagued by jargon. In an effort to help people access the ever-growing hardware community, this post outlines the most commonly used terms in the hardware startup world. If you have suggestions of words you’d like to see on this list feel free to send me a note on Twitter @Ben Einstein.

Product Development

PRS/PRD/Spec (Product Requirements Specification/Document) — there are a long list of names and acronyms for specification documents but they all boil down to the same thing: a document that describes what a product must do in specific detail. Companies that take the time to write a detailed outline of their product requirements universally face fewer issues with design and production. A good spec includes detail in at least seven functional areas, outlined in more detail here.

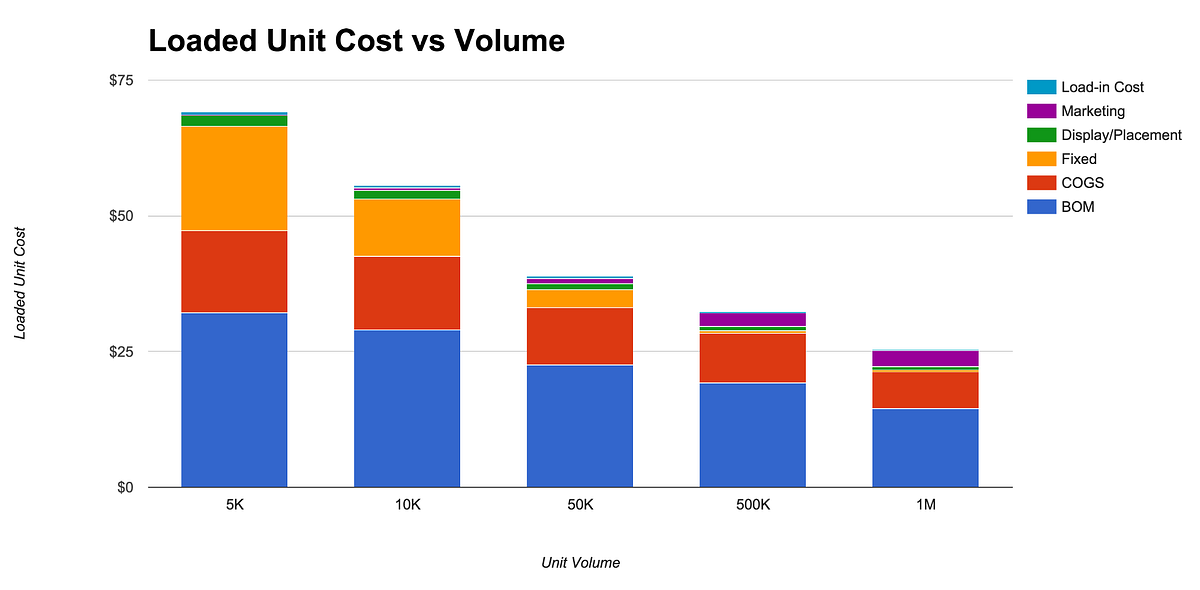

BOM (Bill of Materials) — a list of every part in your product. It’s important to be extremely organized with the BOM as it’s a critical tool for communicating with your manufacturer. Make sure to include costs and lead times. I highly recommend using a cloud based tool like Dragon’s Standard BOM to keep things up to date.

COGS (Cost of Goods Sold) — in financial terms, Cost of Goods is the total amount spent to produce your inventory divided by the number of units in inventory. To simplify, I recommend startups think of COGS as a “BOM plus.” This includes line-items for assembly labor, freight forwarding, logistics, customs, duties, etc.

NPS (Net Promoter Score) — a widely used system to gauge customer interest in your product. By asking customers “how likely are you to recommend our product to a friend?” on a scale of 0 to 10, startups can semi-objectively determine product/market fit. NPS can be statistically relevant with small samples sizes (around 30 people), making it a great tool for prototyping and customer development.

DFM (Design for Manufacturability) — a rigorous process to optimize a part so it can be produced at scale. DFM is focused on reducing per part cost and ensuring quality and consistency.

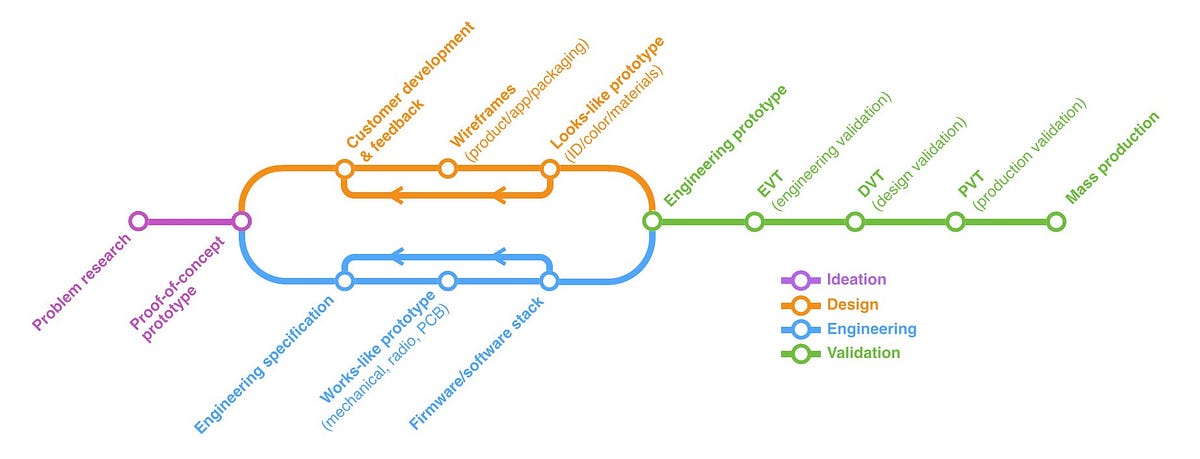

POC (Proof of Concept) — the earliest and most raw prototype to validate that the problem you’re addressing can be solved. Typically made of mostly off-the-shelf parts and not designed to look good or work reliably.

Looks-like/Works-like — complementary prototypes that demonstrate the culmination of your customer development (looks-like) and engineering (works-like) processes. Looks-like prototypes typically look good but are not functional. Works-like prototypes work well and represent functional design intent but do not represent form factor.

EP (Engineering Prototype) — the joining of the looks-like and works-like prototypes. This is typically the highest fidelity prototype made prior to release to the contract manufacturer. EPs are often the most difficult, time consuming, and expensive prototypes to build.

EVT (Engineering Validation Test) — the first of three validation phases during the product development process. EVT prototypes are designed to test the functional aspects of your product against its requirements as outlined in your specification. EVT units are typically assembled by your contract manufacturer on production tooling but in limited volumes (typically 20 units or less).

DVT (Design Validation Test) — the second of three validation phases during the product development process. DVT prototypes are designed to ensure the production process can build units of sufficient quality over a wider set of tests (such as cosmetic, environmental, and reliability). DVT units are made in slightly larger volumes (2–5x of EVT) and test all possible SKUs (colors, sizes, finishes).

PVT (Production Validation Test) — the final stage of validation during the product development process. PVT testing centers on production metrics: scrap rate, build time, jig/fixture performance, packaging, etc. PVT units are typically 10% of first run production volume and are often sold to end customers.

MP (Mass Production) — the phase of product development when units are of high enough quality to be continuously sold. Mass Production often takes place on a long, continuously operating assembly line but is not dependent on absolute production rate, i.e. Boeing is in mass production even though they only produce one 747 per month.

Batch/Cell Production — a type of Mass Production where units are assembled in small, non-continuous batches. Many contract manufacturers use cell production for 5k-10k units, as they’re not yet sure a startup will generate enough product demand to setup a full assembly line.

Utility Patent — the most common patent hardware startups use to protect their inventions in the US and sometimes abroad. Utility patents usually take 3+ years to issue and often cost upwards of $30k. I often recommend companies wait until final launch before filing for full utility patents.

Provisional (Patent) Application — a filing with the US Patent and Trademark Office to secure a filing date up to 12 months prior to the date a full utility patent is filed. Contrary to popular belief, a provisional application is not a type of patent; provisional applications don’t grant you anything if you don’t file a utility patent within 12 months of filing a provisional patent application.

NRE (Non-recurring Engineering) — One-time costs related to engineering. The two most common types of NRE fees are associated with product development (hiring a design firm or contractor) and manufacturing (your CM doing work to finalize a design so it can be produced on their equipment).

MCU (Microcontroller Unit)—an integrated circuit performing a variety of computing tasks inside the product. MCU often refers informally to the primary processor (if there are multiple) that runs the main firmware. This is often the second or third most expensive component in the BOM.

SOC/SOM (System On Chip/System On Module) — a single component on a PCB that houses a microcontroller, memory, input/output control, timing, and power management. For certain product requirements, SOM/SOCs can save significant development time.

UL — an optional safety rating provided by a private US company that has become the de-facto standard for general product safety (especially around power and flammability). While this rating is not required by any federal/government organization, nearly all retailers (and many B2B customers) require a UL rating on all or part of a hardware product prior to purchase. This is especially true for products that don’t have a pre-certified, external power supply.

FCC (Federal Communications Commission) — the federal regulatory body that controls wireless communications for manufactured or imported goods into the US. Nearly all connected devices must perform at least one FCC certification process. The easiest way around a lengthy certification process is to design your wireless product around an RF (wireless) module that is pre-certified by the FCC. You must still go through the FCC verification process but this is far easier (and cheaper) than the certification process. You must display any FCC IDs on both the product and packaging.

CE (Conformité Européenne)—a required marking for any product that is to be imported or sold in the EEA (European Economic Area). Other countries and various international retailers may require this as well. Unlike UL and FCC, CE marks are self-declared by the manufacturer (you in this case) and usually require no outside testing. You are, however, agreeing that your product conforms to a long list of requirements.

SKU (Stock Keeping Unit) — the code applied to a unique product. Each revision, color, and size of a product will have a unique SKU. Increasing the number of SKUs your product has can be extremely dangerous too early in the life of a startup.

Manufacturing

CM (Contract Manufacturer) — a company that manufactures products or components for another company. Startups that hire CMs provide all design requirements to the factory. CMs make the majority of their profit from manual labor and margins on components purchased from other vendors. Example: Apple uses Foxconn as a CM for iPhones.

ODM (Original Device Manufacturer) — a company that designs and manufactures products to be sold to another company with their brand (“white label” products). Startups may approach an ODM as a partner to sell an existing product the manufacturer makes but with the startup’s brand. Example: Cisco uses Flextronics as an ODM for its consumer routers.

OEM (Original Equipment Manufacturer) — a company that designs and sells products made by a number of factories and has the primary relationship with the customer. Hardware startups are “OEMs” for their products, even if those products are manufactured by someone else. Example: Apple is an OEM when selling Macbooks.

Tier 1/2/3 Contract Manufacturer— contract manufacturers grouped by annual revenue:

- Tier 1: ~$1Bn+ (Foxconn, etc)

- Tier 2: ~$200M-$1Bn (Earlylight, etc)

- Tier 3: ~$10M-$200M (Wynnewood, etc)

Contrary to popular belief, Tier 1/2/3 does not denote quality. Oftentimes, young startups are far better off selecting a Tier 2 or Tier 3 CM as their manufacturing partner.

Tier 1/2/3 Supplier — types of suppliers sorted by their place in the supply chain. When Ford builds a car, they purchase assemblies (like a fully-assembled seat) from Tier 1 suppliers, who in turn purchase sub-assemblies (seat motors and headrests) from Tier 2 suppliers, who in turn purchase parts and raw materials (plastic buttons and leather) from Tier 3 suppliers.

MOQ (Minimum Order Quantity) — the minimum number of units a manufacturer or supplier will quote for an initial order. 5,000 units for final assembly is a common number in China, although most CMs really care about total order value rather than number of units.

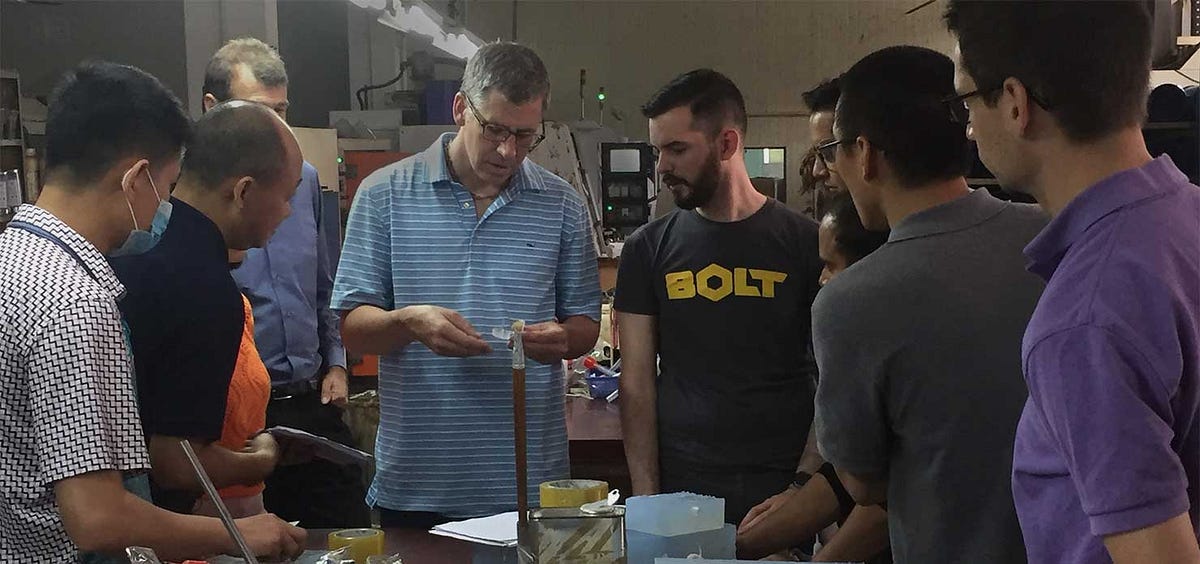

RFQ (Request For Quote) — a formal process used to find a supplier or contract manufacturer. The RFQ process is often misunderstood by startups who simply email a CAD drawing and expect a price. Forging a good relationship with a CM/supplier is a far more complex and nuanced process. To learn more about how to perform a thorough RFQ, head on over to Dragon’s blog post.

MSA (Manufacturing Services Agreement) — a lengthy, legal contract between a startup and their contract manufacturer. MSAs cover many uncomfortable yet critical aspects of the production process: timing, penalties for late deliverables, responsibility for rejected parts, payment terms, line of credit conditions, expectations for future order volume, etc. It’s best for both parties to agree to all terms in the MSA before beginning production although in practice this rarely happens.

Tooling — usually refers to the large metal molds used for mass-producing injection molded plastic or stamped metal parts. Tooling is often the largest single fixed cost for a hardware company during the production process. Here’s good overview of how injection molding works.

PCBA (Printed Circuit Board Assembly) — a printed circuit board (PCB) with all components soldered to it. PCBAs are one of the most common sub-assemblies in modern hardware products and are typically assembled by your CM or a separate EMS (Electronic Manufacturing Services) firm or “board house.”

SMT (Surface Mount Technology) — how most modern electrical components are placed on circuit boards. Older PCBs were designed with hand-soldered “through hole” components.

Ramp —how quickly production volume is increasing. Ramp often looks like a series of S-curves over time, slow at the beginning, fast in the middle, and stabilizing over time until the next big production run.

Yield — percentage of units that meet quality requirements and can be sold to customers. Good production runs typically have yields around 98%. Yield typically includes products that need rework to be sold.

Scrap Rate — percentage of units that must be thrown away due to defects. Scrap rate is the inverse of yield. Scrap rate is sometimes incorrectly used to refer to products that need reworking to be sold.

Terms — payment terms offered by a contract manufacturer, usually expressed in the number of days prior to full payment once the product is handed off to the startup. Most startups on their first production run don’t get any leeway on payment terms; 50% paid on order and 50% paid on delivery is common. Seasoned startups with good CM relationships often get Net 30 or Net 90 terms (see below).

Supply Chain and Logistics

Gift Box — final individual box a customer receives. Gift boxes most commonly refer to retail packaging (products that sit on a shelf in a physical retail store) but can also refer to generic gift boxes from things like Amazon’s “worry free” packaging.

Case/Master Carton — large, double-walled cardboard box that includes more than one gift box (often 20–50 units). Master cartons are then loaded onto pallets for long-haul transport.

FOB (Free/Freight On Board) — time when product ownership transfers from the manufacturer to the startup. If you’re manufacturing in a foreign country, this often happens at the port of export when the CM’s truck drops your cargo off to be loaded onto a ship or plane.

Duties/Customs — fees paid to move freight in and out of a country. Startups can spend as much as 5% of their BOM cost on duties and customs. If your product isn’t documented properly or is shipped by an unusual vendor, customs/duties can be the source of significant shipping delays.

Freight Forwarder — companies that help startups move products between the factory and their distributor’s warehouse. Freight forwarders book space on other people’s vessels (trucks, trains, boats, planes). Their business model is dependent on finding the highest price per unit volume or weight, so it can sometimes be hard to secure good prices for small shipments. Flexport and Haven help startups navigate the complex landscape of freight forwarding.

3PL (Third Party Logistics) — service provider that manages product logistics after importation. 3PLs commonly handle warehousing, inventory management, direct order fulfillment for online sales, and sometimes relationships with distributors. 3PLs usually charge per unit shipped and/or per unit stored in inventory per month.

Shipping Container — large corrugated metal box on large ships and the back of trucks. Commonly called a can. Containers are the smallest single unit of shipment required to get good pricing on long-haul transport.

LTL (Less than Truckload) — shipments that are smaller than a full container but over the 150 lbs limit imposed by the common carriers (Fedex, UPS, etc). LTL shipments are often significantly more expensive per unit and can be difficult to move through international supply chains.

Landed Cost — total cost to produce and deliver one unit. Landed cost includes full COGS plus any transportation, storage/warehousing, fulfillment, insurance, currency conversion, and payment processing fees.

ERP (Enterprise Resource Planning) — software used to manage business operations. For hardware startups, the most important facet of an ERP system is planning for supply chain management and inventory accounting. As companies grow, ERP often includes accounting, sales, procurement, production management, human resources, etc. Netsuite is the most common ERP system for hardware companies.

Marketing and Distribution

Crowdfunding — online platforms used to pre-sell units (often prior to them being fully designed and manufactured). Crowdfunding can be an excellent way to launch certain types of consumer products. Use only after you understand your bill of materials, cost of goods sold, fixed costs, and distribution margin.

PO (Purchase Order) — formal agreement between a customer and supplier to purchase product. Key terms include quantity, cost, lead time, and date of payment. Either used by startups to order product from a CM or by retailers to order product from a startup.

Net 30/90/120 — payment terms provided by both CMs and retailers. Specifies the number of days between delivery of product and full payment.

Distributor — company in the supply chain that purchases products from manufactures and sells them at a significant margin to another business in the supply chain that has end-user relationships, usually a large retailer. Distributors take inventory, store product in their warehouse, and typically pay you immediately. Large retailers often trust distributors more than independent small startups.

Wholesaler — middleman in the supply chain who purchases large quantities of your product either from you directly or a distributor. Wholesalers do not take inventory and don’t pay you until the product is sold to the retailer or end customer. Think of a wholesaler as a ‘broker’, typically taking a relatively small fee for their service and assume little to no risk.

CAC (Customer Acquisition Cost) — cost of acquiring a single user to your product or platform. For most hardware companies, acquisition is defined as the purchase of hardware or software. This is often calculated by taking the entire marketing budget and dividing by the number of units sold.

Channel — how end-customers purchase product. Includes direct sales (straight from a startup), e-tail (online retailers like Amazon), speciality retail (small national retailers with a specific focus like Sur La Table), and big box retail (large national generic retailers like Walmart). Startups must master their channel strategy or “mix” as they grow.

MSRP/List Price (Manufacturer’s Suggested Retail Price) — the highest price an end customer will pay for your product. Retailers will often try to sell your product lower than MSRP. Companies with highly desirable products (like Apple) are able to maintain MSRP across all channels.

GM (Gross margin) — difference between a single unit’s selling price and that unit’s cost of goods, expressed as a percentage. If the amount is expressed in a dollar amount, it’s typically called gross profit. If a product has a cost of goods of $33 and sells for $100 it has a 67% gross margin.

Sell-in — number of units a retailer agrees to order from a startup. In most cases, the retailer doesn’t pay startups for units until they sell to the end customer. Sell-in is typically expressed as a number of units from a purchase order.

Sell-through — the moment a retailer sells a unit to an end-customer. Startups recognize revenue once sell-through occurs. Sell-through is typically expressed as a percentage vs sell-in.

Lift — an increase in sales of a product, usually due to marketing. Often expressed as a percentage increase.

Backstock — number of units required by retailers to be held in inventory. In many POs, retailers will require an additional 20-50% of an order’s volume to be readily available. Oftentimes this is a buried term that can be detrimental to startups with low inventory.

EOL (End Of Life) — the moment a product is no longer produced for new end customers. Most consumer electronic products have an 18 month life cycle.

MRR/ARR (Monthly/Annual Recurring Revenue) — revenue generated from ongoing services after an initial hardware sale. Recurring revenue creates ~5–10x more enterprise value than one-time hardware revenue due to future revenue potential.

Attach Rate — percentage of users that subscribe to an additional service after initial product purchase. Successful hardware companies have attach rates around 30–35% for optional services.

LTV/CLV (Lifetime Value of a Customer) — total value of a customer over their entire life. This includes original hardware sales, subscription revenue, and accessory sales. LTV can be complex to calculate, requiring knowledge of customer churn, how margins change over time, and user retention cost.

Ben Einstein was one of the founders of Bolt. You can find him on LinkedIn.

Bolt invests at the intersection of the digital and physical world.