Whether in fitness, food, or farming, we’re seeing tremendous advances in how technology is helping people live healthier lives. Consumer demand for more sustainable food has rippled through the supply chain, challenging us to grow plants and raise livestock with better tech and a smaller footprint.

At FYTO, founder Jason Prapas and team are blending agriculture, robotics, and biology to grow nutrient-dense, non-GMO aquatic crops using automated cultivation and harvesting systems. These crops empower farmers to feed their animals with improved nutrition, better price stability, and a drastically lower environmental footprint than ever before. We’re proud to have been their first investor.

I sat down with Jason to explore the inspiration for FYTO and understand why animal feed is so critical to modernizing our food supply system.

(And FYTO is hiring! Check out current openings here.)

Kate McAndrew: A fascinating journey led you to founding FYTO. Take me back. What’s the origin story?

Jason Prapas: I had an amazing first job out of college with GreenFuel, which was the first ever algae biofuel startup. It kind of ruined me in terms of ever working a traditional corporate job. And it definitely sparked a desire to find ways to leverage nature to improve the status quo. Later, as part of my PhD, I had the chance both to visit and live in many different countries around the world in an effort to identify potential clean energy technology solutions for underserved, primarily agrarian, communities. A few years later, when I was living and working in India, I came to appreciate just how stressful and unpredictable it was for livestock farmers to feed their animals. And I realized this was a common pain point for farmers globally, whether they’re in Mumbai or Sacramento. It was a real eye opener for me.

The final piece of the puzzle came when I was working at MIT. Surrounded by such brilliant researchers, you can’t help but think about real step-changes in technology that might benefit humanity. At that point, I started to envision a new kind of sustainable technology that could help farmers at a truly global scale.

Kate: One of the themes we’ve been investing in for some time now (and are excited to double down on) is reimagining supply chains for sustainability. That’s central to FYTO’s mission. How would you describe what FYTO is doing?

We’re now operating what we think is one of the world’s first automated plant protein production facilities.

Jason Prapas: Right now, farmers are dependent on this very complicated, very inefficient global trade of commodities. And price shocks happen all the time. In the not-too-distant-future, FYTO imagines a really different way of growing these fundamental ingredients in our food supply – a way that can create abundance using much fewer resources. To date, we’re primarily focused on the protein, carbohydrates, vitamins, and minerals needed to feed cows. There are about a billion cows on the planet right now so that’s a lot of mouths to feed…

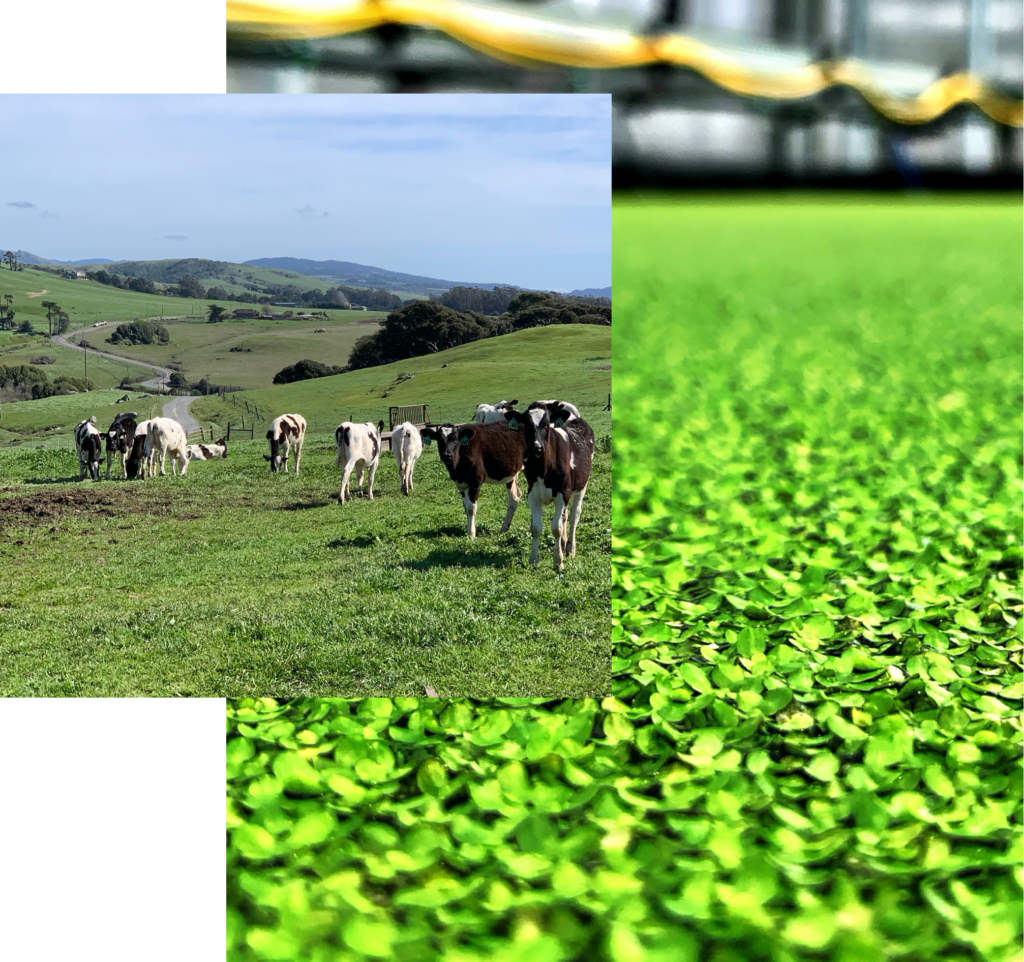

We’re providing a solution where farmers can devote a very small fraction of the land they already have, and use the manure they already have, to grow specialized aquatic plants that will feed their livestock through our automated technology platform. The beauty of our aquatic plants is they can grow on the worst land you can imagine, because they’re in an engineered pond, not in soil, so we don’t compete for arable land. We’re now operating what we think is one of the world’s first automated plant protein production facilities.

Kate: The phrase automated plant protein production facility is a great synthesis of what you do. At a high-level, you’re re-imagining the supply chain – the inputs and the outputs – the complete location of where the food is coming from and the energy equation that sits alongside all of that. How are you leveraging technology to accomplish this?

Jason: We have controlled growing conditions for the aquatic plants. We’re essentially automating any activity that would normally be done by farm workers – and the unique nature of our aquatic crops allows us to do this rapidly. So when you think about planting corn, farmers have to till the field. They have to plant seed. They have to fertilize. They have to irrigate. And THEN they have an all-or-nothing seasonal harvest. But with aquatic plants, we don’t till because we don’t have soil. We don’t seed because our plants reproduce asexually. We don’t use any synthetic fertilizer as we’ve figured out how to process livestock manure and flow it into our growth systems in a targeted way. And we can harvest multiple times per week, year-round.

To do this, we’re leveraging an array of technologies available today – advanced sensors, PLCs, computer vision, and robotics at a price that’s astronomically lower than it was ten years ago. So we have a process that makes economic sense. And we’ve started to hit our stride in terms of how we can do this at scale. We’re currently field-testing our FYTObot which is a purpose built robotics system – hardware and software that has been designed specifically to tend to these crops and to harvest them at the rate that allows them to continue to thrive while making really high quality, high nutrient density agricultural products.

Kate: FYTO is currently based here in Northern California, in Petaluma, which is home to some of the most loved, cared for cows in America. They’re living very happy lives. What drove your decision to be there?

Jason: I had been iteratively designing in some of the most challenging communities in the world in terms of being off-grid, which sort of forged FYTO in the fire. Farmers in Northern California have their own set of challenges but it’s also a truly pioneering place when it comes to sustainable agriculture and technology adoption. Our vision is to bring this solution to communities broadly around the world. But we need to nail it here before we scale it there. The last thing I want to do is perpetuate a solution that isn’t fully baked or hitting the mark. So the opportunity here is to learn from the really innovative farmers in Marin and Sonoma Counties and to be in a place where we can prototype and develop technologies at a very rapid clip, and set the gold standard for the rest of the industry. The end goal is the same.

To me it’s a dream come true to be working on a problem I really care about with customers that I admire and to be able to engage with a multidisciplinary team that spans biology, engineering, computer science, agronomy, and business. In dealing with a really all-encompassing problem, you have to engage so many different types of thinkers to make it work. That’s been very rewarding. I continue to really enjoy coming to the sites every day.

The opportunity here is to learn from the really innovative farmers in Marin and Sonoma Counties and to be in a place where we can prototype and develop technologies at a very rapid clip, and set the gold standard for the rest of the industry.

Kate: Right. At the time we were investing in FYTO, we noticed a lot of companies going deep on the material science biology side of agriculture whereas you had a real bullishness for growing robust existing plants. This allows FYTO to participate in the huge cultural wave toward organic and beyond organic.

Jason: We’ve focused on identifying and growing plants that are naturally impressive when it comes to yield and quality. So we don’t have to worry about genetic modification or advanced material science biotechnology in that way. I would also say there’s nothing about our platform that would exclude that in the future, but we don’t find the need to take those routes yet. And since we don’t, we are able to serve the organic sector, which is the part of animal agriculture that’s in a really exciting growth curve be it dairy, eggs, or meat.

When you look at the stringent requirements of organic, a dairy farmer has to feed their cows certified organic produce that requires a very similar process to what goes into the produce you’ll find at Whole Foods. It’s really difficult to source those ingredients at a price the farmer can afford. So one of the things we see ourselves helping with is really democratizing organic for a much wider range of farmers. That’s an important part of our mission.

(This interview has been edited and condensed)

Bolt invests at the intersection of the digital and physical world.